- Home

- About Us

About Us

One-stop card customization

Shenzhen DCCO Technology Co., Ltd. is a company specializing in the search, sales and service of Java cards, IC cards, ID cards, contact cards, NFC tags, NFC wristbands, card printers, and card readers. Our main products are Java cards and full-panel printable IC ID cards, which have consistent praise and repurchase rates.

We have experienced staff dedicated to strict quality control and thoughtful customer service, ready to discuss your requirements and ensure complete customer satisfaction. There is strict quality control before sending any goods (even samples).

Quick response

Fastest delivery time

Card range

Already cooperated customers

Our qualification certificate

Our products are manufactured to the highest quality and manufacturing standards and rigorously tested so you don’t have to worry about anything.

Why choose us?

We have a comprehensive range of products that can meet the application needs of different industries. At the same time, we have standardized processes and experienced employees on our production lines to manufacture your products and provide you with thoughtful customer service. In addition, our products are exported to the United States, Europe, the Middle East and other places, and we have global export capabilities.

- Global export capabilities

- Strict quality control

- Comprehensive product

- Standardized card printing

Provides Java Card and full panel solutions

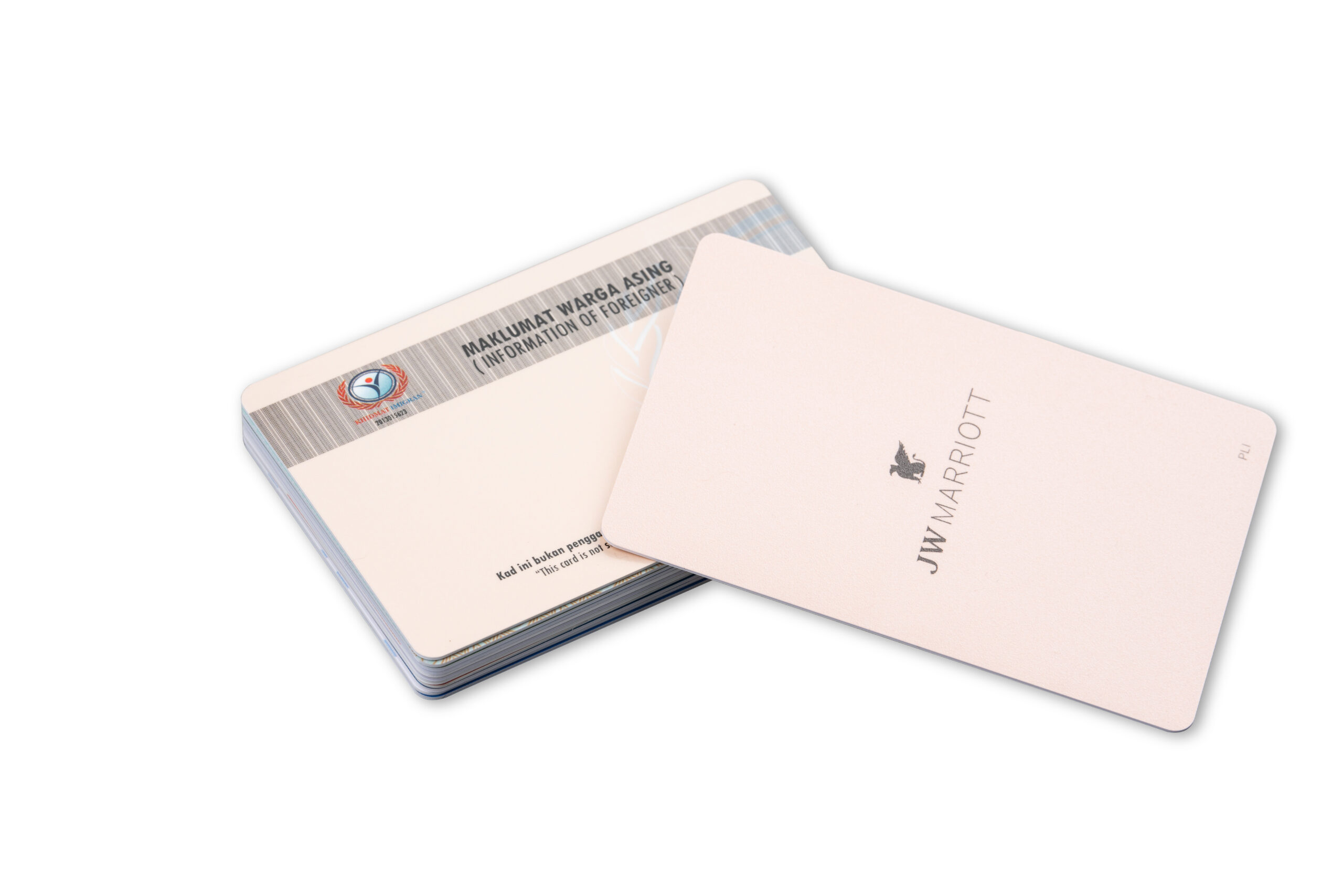

The Java Cards we offer are widely used in different markets such as wireless telecommunications within SIM cards and embedded SIMs, payments within bank cards and NFC mobile payments, as well as ID cards, medical cards, and passports, among others.

- Bank card

- ID card

- SIM card

- Public transportation card

- Holiday celebration non-woven wristbands

- Hotel door lock card

production workshop

Card Production Process

Producing IC cards involves a meticulous and multifaceted process integrating technology, precision, and security features. From the initial design stages to the distribution of finished IC cards, each step plays a vital role in ensuring these critical devices’ quality, functionality, and safety.

1. Design planning:

At this stage we need to design and plan the specifications and functions of the IC card. This includes determining the type of integrated circuit, card size, security features and intended application. Factors such as card materials, visual elements and branding are also considered during the design phase.

2. Chip embedding:

At this stage the chip is embedded into the card. This microchip contains an integrated circuit and an antenna. The embedding process involves precise placement of the chip onto the card substrate. Various methods, including direct bonding or encapsulation, can be used to secure the RFID chip or other chips to the card.

3. Card lamination:

IC cards are laminated to enhance durability and protect embedded components. Both sides of the card are coated with multiple layers of transparent film or laminate that encapsulates the embedded circuitry. This protects the IC and resists physical wear, environmental factors, and tampering.

4. Personalization and Encoding:

Personalization adds a unique identifier to each IC card, such as cardholder information, account details, or access credentials. This step involves printing variable data, including names, photos, and other personalized information. Additionally, IC cards are encoded with specific data relevant to their intended application, such as financial information or access rights.

5. Quality control:

It is crucial to ensure the quality and functionality of IC cards. Strict testing and quality control measures are implemented at all stages of production. This includes functional testing of embedded ICs, verification of personalization data, and assessment of card durability. Any flaws or inconsistencies will be identified and resolved before moving to the next phase.

7. Card sorting:

Finishing touches are carried out at this stage, including applying security features such as holograms, magnetic stripes or RFID components. These features add an extra layer of protection and functionality to the IC card based on its intended use. The final look is polished and any additional printing or branding elements added.

8. Packaging and delivery:

The completed IC card is carefully packaged to prevent damage during transportation and distribution. Packaging may include a protective layer, instructions and any supplementary materials. The delivery stage ensures that the IC card reaches its intended destination safely and efficiently.

Online 24 hours a day, you are welcome to inquire and place orders to get samples!

Get a quote in as fast as 3 hours!